How to use

How to use

- Precautions for using the tools

-

- This cemented carbide bite is based on the S45C of the workpiece. (Other workpieces should be discussed with us.)

- Do not tighten the tightening bolts excessively when tightening the carbide bite.

- Maintain the mechanical vertical and horizontal state before installing the bite holder.

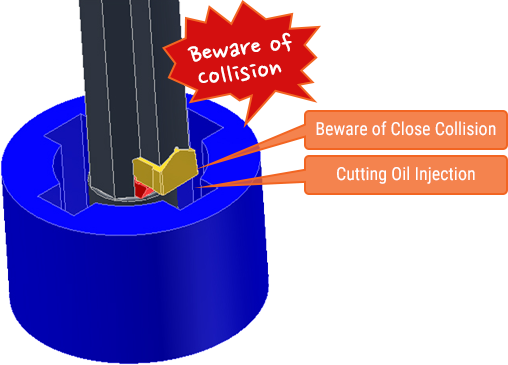

- Be careful not to collide with the workpiece when approaching the carbide bite to it during initial setting.

- Be sure to inject the cutting oil when cutting is in progress (built-up edge occurs).

- Use the best quality L-wrench for tightening the bite.

- Check the loosening and sagging of the tool tightening bolt after the initial cutting 2~5 times.

- Cutting speed: process 1.5 ~ 2 times faster than HSS.

- 1 depth of cut range: 0.03 ~0.10(mm) (to adjust considering the condition of the workpieces on site).

- Repeated finishing: 4~5 times are appropriate (excessive repeated finishing accelerates bite wear).

- If abnormal noise occurs during cutting process, immediately stop processing and check the bite status.

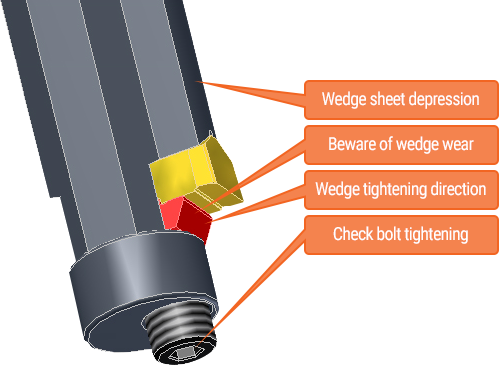

- Precautions for bite tightening

-

- When tightening the bite to the holder, do not tighten it excessively.

- The bolts are made of special steel of the highest grade, so the best quality L wrench should be used.

- After the initial cutting 2~5 times, check the loosening state of the bite tightening bolt.

- The bolts for tool fastening are made of special materials. When they are damaged or lost, they should be replaced with the standard items provided by us.

- Precautions in Performing Cutting

-

- Be careful not to collide with the workpiece when approaching the carbide bite to it during initial setting.

- Inject sufficient cutting oil during the cutting process.

- Observe the depth of cut range (0.03~ 0.10 mm) during the cutting process.

- During the cutting process, the processed chips should be managed to be sufficiently discharged.

- Excessive repeated cuttings should be avoided when finishing work.