Greeting

Greeting

We are a company that specializes in manufacturing and supplying tools for slotter machine keyslot cutting.

shank holder, insert tip, peripheral device

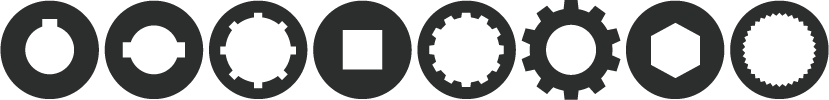

In general, in all industrial machinery sectors, the power shaft for transmission of original power (rotation power) from the core driving source (e.g. electric motors, motors) and mechanical component parts for transmission of driving force around it, such as gears, pulleys, couplings, timing pulleys, crankshafts, etc., and various types of keyslots (parallel keyslots, vandal keyslots, spline keyslots, taper keyslots, etc.), which are the essential intermediate elements for power transmission, are used. Combined with the driven bodies, they transmit the rotational force of the original driving source without loss. In order to assemble the key slots, which are the essential mechanical components, various types of key slot cutting are performed by using the key slot cutting tools of the slotter machine.

- Key Slot

Unfortunately, even today, the most commonly used cutting tool for keyslot cutting in general production sites is using the heat-treated and hardened HIGH SPEED STEEL, the conventional cutting tool steel grade (also called HSS or Kansei). This conventional cutting tool have fatal defects in keyslot cutting process.

For example, manufacturing the finished bite of HSS standard dimensions requires highly skilled experts and excessive production time. Also, it has lots of unreasonable problems, such as difficulty in managing the standard dimensions of the bite, high production cost, impossibility of precision dimension customization, shortage of tool life, insufficient quality level, inability to respond quickly to small quantity batch production, excessive tool preparation time, high recycling costs, and environmental pollution, etc..

Therefore, our company has developed the patent for keyslot cutting dedicated tools (holders, insert tips) and peripheral devices for slotter machines, the breakthrough technology comprehensively improving the chronic problems of conventional keyslot cutting tools based on the HSS materials, and now it is available for standard production.

Key features of our keyslot cutting tools are; First, the use of ultra-fine cemented carbide as the raw material, a cutting-edge cutting tool material. Second, the establishment of the standardized production system, developing insert tip type tools so that even unskilled people can use it easily and conveniently. Third, cemented carbide insert tip holder shank and peripheral devices, which are essential mechanical devices for maximizing the advantages, have also been developed and launched.

These standard tools for keyslot cutting dedicated slotting machine tools have comprehensively improved the chronic problems of conventional slotter machine tools. We firmly believe that our products will contribute to increasing your productivity (reduction of tool manufacturing cost, tool setting time and cutting process time, securing tool durability, improvement of production environment) and to maintaining excellent quality level of keyslot processing products (prevention of defects, securing the standard tolerance level, increasing bite durability, improving of improving of the phenomenon of pushing the bite back, reducing regenerating time, etc.).

Since the patent application in 2009, we have established and developed the standardized production system, and we are launching new products meeting the production site demand through continuous research and development.

We promise that we will actively respond to customer needs by further enhancing our R&D and technology to be a world-class professional slotting tool manufacturing company along with your growth. We look forward to your continuous interest and support.

All STS employees